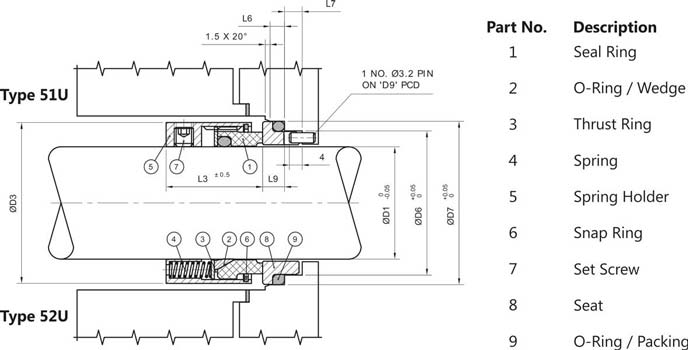

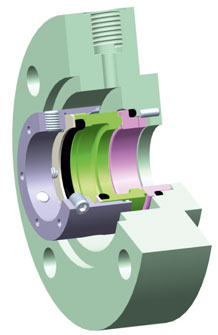

Multi Spring Mechanical Seal

Seal Type 51U is recommended for clean media application. Seal Type 52U is Standard for using where Corrosive Liquid are being Processed. PTFE Wedge Construction of the Secondary Sealing Member provides Universal service application. Construction of these Seal designs holds whole Rotary Parts together with the help of Snap Rings which is make easiest of Installation and Removal. These Type of Seal designed and used for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts. Multi Spring Mechanical Seal are carefully designed at Superproof Seals Engineering.

Features

Unbalance Pusher Seals available in Single and Dual. Configuration used for Sealing Environmentally. Dual Directional. Mechanical Seal Drive – Reduces Slippage on Shaft or Sleeve to Eliminate Galling and Premature Wear . Components in Cartridge design are builds for the Highest Reliability and simple Installation. Flushing Ports helps to reduces the Heat for Uniform Face Cooling. Seal Type 51U is ‘O’ Ring Seal design which helps to Eliminate Scoring on Shaft and Sleeve area. Use of ‘O’ Ring Design is depends on suitable applications. Seal Type 52U is Wedge design which helps to Creates Positive Seal use in Extreme Temperature, Chemical application. Using of suitable Coating on sealing area to Eliminate Scoring on Shaft and Sleeve

Materials

- Seal Ring Faces : Cabon, SiC and TC

- Seat Faces : Ceramic, SiC and TC

- Elastomer : Viton, PTFE, GFT, EPDM, NBR, Buna-N and FFKM

- MOC : SS 316, Hast -C and Alloy – 20

Operatiing Capabilities

- Shaft Dia. : 10mm to 100mm

- Pressure : Up to 10 bar

- Temperature : -20°C to 260°C (Depending upon Elastomer)

- Speed: 3000 r.p.m.